Aluminium Extrusion Profiles and Their Applications in the Windows and Doors Segment

Extruded aluminum profiles have made a significant impact in construction and engineering, providing high-quality adaptability and durability for aesthetics seen practically around every corner of the market, specifically when it comes to window and door manufacture. The new technology is based on the need for development of a process to extrude an aluminum alloy through a die specifically designed and formed into desired profile, shape, and size. Results is a continuous sections or profiles with constant cross-sectional area structural uniformity and integrity that it possesses.

Through extrusion, the high aesthetic values of aluminum are combined with the properties of function to improve material properties and become a more compliant building medium for use in many applications. This makes it a wonderful design material for architects and builders who want to stretch their imagination regarding durability and longevity within their project. Another element that adds green feature to its advantages is aluminum extrusion profiles being 100% recyclable material implying sustainability in construction application.

The Advantages of Aluminium Extrusion Profiles

Currently, aluminum extrusion profiles are used more in construction and design due to their benefits over traditional materials such as wood, steel or PVC. One of the worst things about this material is its associated strength potential with weight it being unable to be outdone, so that in current architecture designs where stability and lightness are key issues, steel remains a number one bother. Aluminum's high strength-to-weight ratio, makes it ideal for the construction of components such as windows and doors that must be sturdy to ensure security but also light enough for smooth operation.

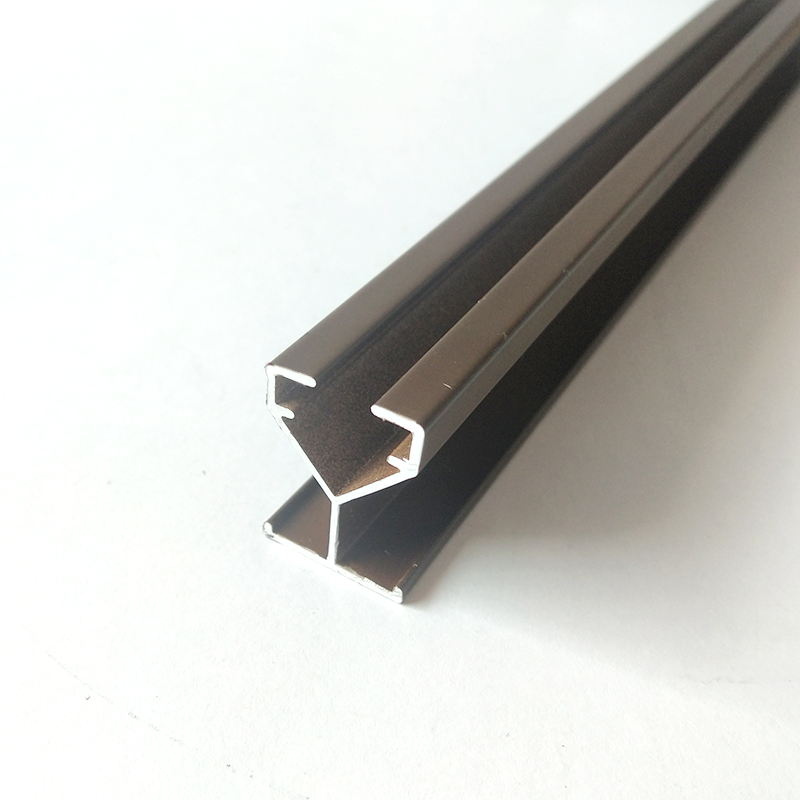

Aluminum also has another feature that is important, its ductility, allows the construction of large but stable structures, a must in contemporary architecture. With this, the designers can come up with intricate and beautiful designs that would be a lot harder to do using heavier or less pliable materials. The fact that this alloy can be extruded into multiple shapes and sizes allows for customized architectural components; thus, the demands of a particular design can be achieved without sacrificing structural integrity.

Aluminum structures also have another major benefit they require minimal labor for their upkeep than other materials. The profiles require very little maintenance — primarily routine cleaning; they do not also warrant supplementary applications of paints or sealers to maintain their appearance or structural integrity. The low level of upkeep reduces care expenses and hassle for a building owner in the long run, making one more reason to use aluminum an affordable option amidst residential and commercial construction projects.

In addition to that, the possibilities of customization with aluminum are practically endless. Thanks to extrusion, the specific requirements of any project can be perfectly addressed; and so, new architectural ideas and custom solutions are enabled. This is coupled with the aesthetic adaptability of aluminum: advanced treatment methods like anodizing, painting or powder-coating not only provide an aesthetically pleasing look but also act as the second line of defence against environmental attacks. These finishes are available for a wide range of colors and textures, allowing architects and designers to perfectly execute every project in detail.

Aluminum extrusion has long provided a combination of strength, lightness, flexibility, corrosion resistance, low maintenance and aesthetic versatility superior to many older building materials in window and door construction as well as energy efficiency. These qualities have rendered aluminum as truly one of the most valuable resources in modern architecture, where performance and aesthetics are paramount.

Applications of Aluminium Extrusion Profiles in Windows

Indeed, the field of window engineering & manufacture has certain features and possibilities that can be provided only with an aluminium profile extrusion. Yes, particularly an aluminium profile can make them very functional with its frames, as well as aesthetic solutions by contemporary architectural needs. A specific example is the malleability that the extrusion process provides in terms of aluminium, for which many complex shapes can be formed to allow assembly of panoramic windows. Pillars are developed by slim yet strong aluminium accounts, which fully open vast views while providing complete architectural safety and functional.

That window frame can be made to suit any opening size, thanks to the design flexibility in aluminum extrusions, making them compatible with many styles of windows. Aluminum will be able to easily accommodate any number of window types, from tilt-and-turn to casement to sliding and fixed. Aluminum also fits a wide range of needs and architectural styles which is why it remains one of the more popular building materials for both residential and commercial buildings.

In addition, window performance has also been viewed in terms of thermal efficiency and phenolic resins are used in reaction to these properties by creating these types of aluminum extrusions. This is the case with the thermal break in Furmanite's aluminium windows. In them, thermally breaks of frames and double or triple-glazing very efficiently limit thermal transfer. This improvement helps maintain the inside temperature more consistently, requiring less energy and allowing people to feel more comfortable inside. Attributes such as these form the basis of why aluminum extrusions can be considered the most superior solution for modern building practices where separating energy efficiency from a flexible aesthetic is key.

Applications of Aluminium Extrusion Profiles in Doors

Aluminum profiles of extrusion are certainly an indispensable component of door making, owing to the unfathomable application in different domain as well as functionality. From large, striking front doors to smooth sliding patio doors, Aluminium gives flexibility for a variety of both design and functional requirements. Security is a fundamental principle at access points in both private and commercial properties; intrinsic robustness provides the basis for it. The mold-ability of aluminum helps manufacturers in manufacturing various styles of doors; from big glass paneled doors providing openness and light to decorative entry doors which bring about curbs appeal and style suing itself up or plant a Clark Kent level alter ego around architecture.

It is particularly great for large doors like bi-folding or sliding doors. However, large doors in aluminium feel surprisingly light in operation thanks to the lower weight. They are, however, strong doors that will endure frequent usage and will stand up very well in high-traffic areas of both commercial buildings as well as residential homes with no loss of ease operability.

Aluminum entrance doors have advanced security systems, combined with multi-point locking devices and hardened profiles for strength and durability. And this is why those features are the reason why aluminium doors are more secure than other materials in all probability, not reinforced as these.

Moreover, the finishes on aluminum doors are not merely to make them more visually appealing; they counter environmental elements and weathering effects. Through these very finishes fulfills their obligations so that the doors are attractive aesthetically once fitted rather than emitting shoot in such a fashion forevermore structurally stable the majority of through their useful life. As a result, the Aluminum door options are also durable, aesthetically pleasing, secure and relevant to be used for several kinds of applications. These have gained popularity in contemporary construction and design.

Conclusion

Aluminum extrusion profiles are the foundation of windows and doors construction, due to there excellent properties and versatility. Offering great benefits with its natural strength, versatility and corrosion-resistance properties makes it a very good option for the demand of modern construction. Aluminum somehow stands the test of environmental challenges and retains itself as aesthetic too and increases the value of building projects.

However, in addition to strengthening, appropriate for modern construction is one of the key factors that make the profiles adaptable in design. These profiles are diverse in shape and form and can be designed to meet highly specific requirements that an architect or designer may have, all while achieving unique aesthetic styles. In terms of application, aluminum extrusions satisfy from big panoramic window frames to exquisite door designs.

In addition, indoors the amount of energy efficiency aluminum helps. Thermal breaks and better glazing methods have significantly improved the insulation properties of aluminum window and door frames. This not only keeps the indoor temperatures stable, but this means saving of energies, hence reducing utility bills and carbon footprint.

With Aluminum extrusion moving with time, so are the uses and benefits of this alloy. Extrusions have probably continued to gain even better performance, longevity and sustainability through engineering innovations in the extrusion process as well as surface treatment steps. This is an ongoing development—one where the role of aluminum in the future of architectural design and construction will be much more integrated than simply providing vast opportunities for custom and energy-efficient building envelopes. The ongoing disclosure of the progress of technology in aluminum extrusion is promising to release new potentials and making it more vital material in construction industry.

EN

EN